Sales & Operations Planning

Stay competitive and gain financial benefits with Sales & Operations Planning.

S&OP: balancing supply and demand

As a manufacturing company, there can be many challenges in balancing supply and demand. These can range from missing sales forecasts, backorders, extended lead times, increasing inventory holding costs and capacity constraints. Especially after a period of international COVID-19 lockdowns, rising raw material prices, supply chain disruptions, inflation, and war, it can be difficult to balance supply and demand while maintaining a competitive business.

Sales & Operations Planning (S&OP) strengthens the balance of supply and demand while reducing costs in your supply chain. Furthermore, S&OP gears your company towards the most important business discipline of our time; agility.

We have gained a completely different insight between departments as everyone has access to the same data, increasing cooperation and understanding across the organisation. There are no longer frustrations regarding lack of data, and the data quality has improved significantly.

Logistics Specialist

All Sales & Operations Planning-data in one solution

Combining all company data in VIS Performance allows you to identify and analyze synergies across the value chain.

VIS Performance enables efficient planning and provides a transparent insight across departments for increased collaboration, making it easier to find ways to reduce costs and streamline processes.

- Actual Sales Compared to Production

- Back Orders

- Stock Level/-Inventory

- Commodity Prices

- Delivery Costs

- Sales-, Supply- and Production Forecasts

- Production Capacity

- Scenario Planning

- Income Statement

- Balance

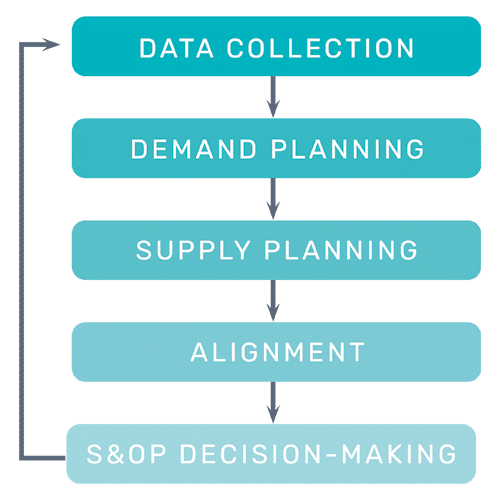

S&OP in 5 steps with VIS Performance

The classic challenge in many companies is that sales measure turnover, operations measure in units, and management measures the overall budget. With VIS Performance, the individual measurement points are combined and transformed into a common action plan and objectives, which increases efficiency and competitiveness while reducing costs.

By simply following 5 steps and implementing them in a monthly cycle, you can ensure coherence between departments across the value chain, so there are no imbalances between sales, marketing, product development, production and procurement.

DATA COLLECTION

S&OP requires large amounts of data. VIS Performance combines all data across source systems in one solution, providing a transparent insight to actual sales compared to production, back orders, stock levels and much more.

DATA COLLECTION

S&OP requires large amounts of data. VIS Performance combines all data across source systems in one solution, providing a transparent insight to actual sales compared to production, back orders, stock levels and much more.

DEMAND PLANNING

Combining all company data across the value chain in one solution provides a transparent insight to the current situation, which enhances Demand Planning.

With multi-user access and write-back functionality, the Sales Forecast can be submitted by the sales team directly in VIS Performance. All data from the data collection as well as growth targets, marketing plans and new products in the portfolio is visualized in the software, making it easier for the sales team to make a realistic Sales Forecast.

By combining Demand Planning with all company data in one solution, Sales Forecasts automatically combines with the current stock levels.

DEMAND PLANNING

Combining all company data across the value chain in one solution provides a transparent insight to the current situation, which enhances Demand Planning.

With multi-user access and write-back functionality, the Sales Forecast can be submitted by the sales team directly in VIS Performance. All data from the data collection as well as growth targets, marketing plans and new products in the portfolio is visualized in the software, making it easier for the sales team to make a realistic Sales Forecast.

By combining Demand Planning with all company data in one solution, Sales Forecasts automatically combines with the current stock levels.

SUPPLY PLANNING

With a valid and transparent insight to the current situation and expectations for the future, Supply Planning can begin matching the needs from Demand Planning.

With accurate and data-based Sales Forecasts combined with current stock levels, Operations can evaluate available capacity and plan for procurement and production.

SUPPLY PLANNING

With a valid and transparent insight to the current situation and expectations for the future, Supply Planning can begin matching the needs from Demand Planning.

With accurate and data-based Sales Forecasts combined with current stock levels, Operations can evaluate available capacity and plan for procurement and production.

ALIGNMENT

With a data-based insight into the value chain, with data input from both sales, procurement, and production, supply and demand can be matched.

I a reconciliation between sales, procurement, and production, a proposal is prepared on how any imbalances can be addressed using the simulation tool in VIS Performance.

ALIGNMENT

With a data-based insight into the value chain, with data input from both sales, procurement, and production, supply and demand can be matched.

I a reconciliation between sales, procurement, and production, a proposal is prepared on how any imbalances can be addressed using the simulation tool in VIS Performance.

S&OP DECISION-MAKING

The S&OP-Manager presents the overall decision-making basis to corporate, who subsequently have a data-based, valid decision-making basis for growth objectives and profitability.

S&OP DECISION-MAKING

The S&OP-Manager presents the overall decision-making basis to corporate, who subsequently have a data-based, valid decision-making basis for growth objectives and profitability.

Increased interaction reduces costs

By gathering all data across the value chain, collaboration is increased across the organization. By creating synergy across sales, procurement, production and finance, based on valid data and forecasts, costs are reduced in your supply chain in a future-proof solution.

Success med S&OP

S&OP is a critical cross-functional planning process that can improve a company’s balancing of demand and supply of goods. It is a process that helps develop a tactical plan that can contribute to creating competitive advantages.

Success criteria:

It is crucial that the S&OP process is treated as an overall company process and not perceived as something that happens in isolation in the supply chain or sales. In addition, one should be aware of the following success criteria:

- S&OP needs to be anchored in top management.

- Ensure strategic alignment (S&OP needs to be linked to the overall strategy).

- Ensure organizational alignment (breakdown silos, integration, clear roles and responsibilities).

- Focus on performance management (correct measurements – valid and reliable data).

- Ensure sharp project planning (start with a pilot project, quality in data and information, precise, complete, and timely exchange of data and information).

- Focus on organizational readiness (conflict management, continuous improvement, change management, training and education).

- Focus on the right meeting culture (regular S&OP meetings, meeting agendas, and active participation).

Focus on behavior

To fulfill the full potential of an S&OP process, traditional KPIs should be supplemented with behavioral indicators, the so-called Key Behavioral Indicators (KBIs). What actual behavioral changes are needed to ensure that work is done most effectively towards meeting performance targets? One should avoid too much focus on hard metrics at the expense of soft values and the people who deliver the work. It should be balanced.

Behavioral indicators can be used at the individual level, in the relationship between two employees, and for a group. Behavioral indicators should focus on the desired behavior among employees that is needed to support actions that meet the KPIs. Concrete KBIs can include active participation in meetings, avoiding interrupting each other, and making decisions based on facts rather than emotions.

Choose a supporting tool

When behavior and data alignes

There is a significant behavioral change required within the company in order to fulfill the full potential of an S&OP process, and thus also the company’s performance goals.

To enable this internal behavioral change, there is need for a platform or tool that can support the process and provide data.

Book a demonstration of VIS Performance, and experience how your S&OP process can be empowered.

Request a demo

Save time and improve accuracy with VIS Performance. Discover our platform by filling in your information.

discover our solution:

- Budgeting and forecasting

- Monthly Reporting

- Consolidation

- Sales & Operations Planning

- Customized dashboards

- Return on investment

Solid customer base

Our customers are the core of our business, and they have been since the very beginning in 1993.